- Capabilities

What We Do Best

Precision plastic solutions, designed for performance and built to scale.

Customer Satisfaction Rate:

98%

Capabilities

End-to-End Injection Molding Services

At Poliform, our capabilities are built around delivering end-to-end plastic injection molding services from tooling and prototyping to high-volume production and final assembly. Every part we make reflects our commitment to accuracy, efficiency, and customer-driven innovation.

Whether you’re developing a new product or optimizing an existing one, we offer the flexibility, technical depth, and infrastructure to bring your ideas to life at any scale, with zero compromise on quality.

Our Core Capabilities

Complete Solutions: From Concept to Component

Explore the key areas that define our manufacturing expertise:

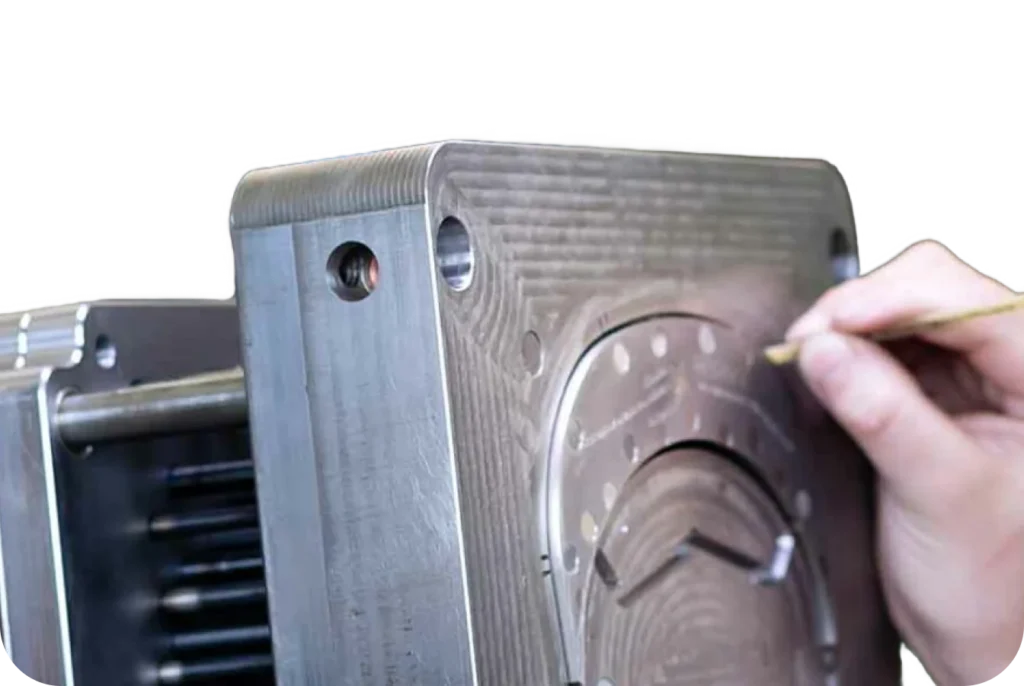

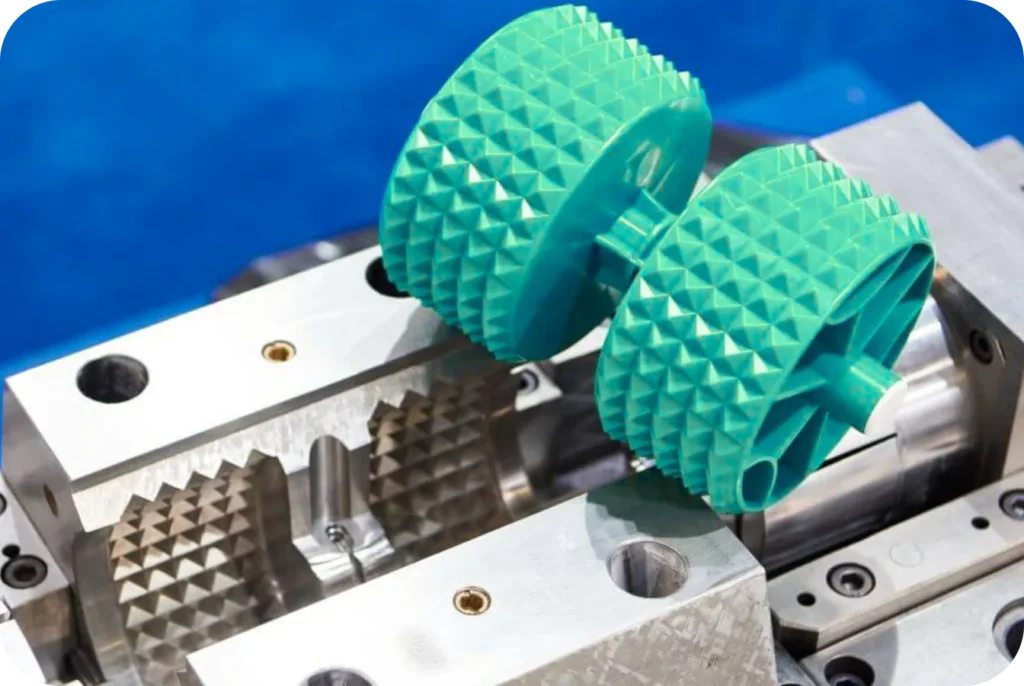

Mold Development

Custom-designed molds built to exact specifications for high-performance plastic parts.

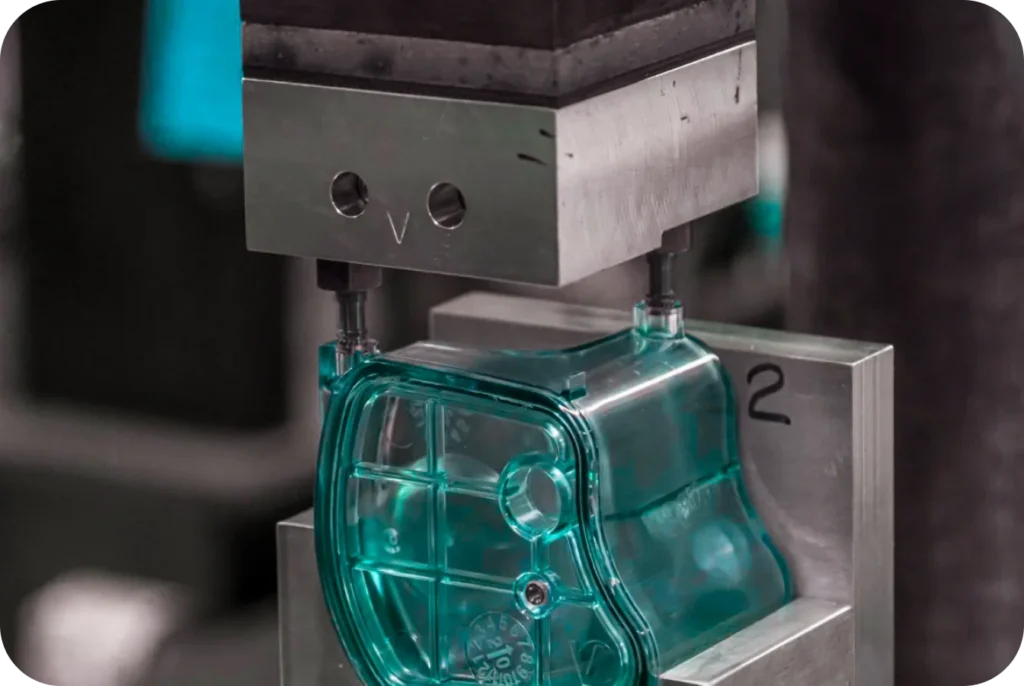

Injection Molding

Advanced, energy-efficient machinery delivering high-precision components at industrial scale.

Post-Mold Assembly

Integrated assembly and finishing services for ready-to-use parts.

New Product Development

From ideation and DFM to prototyping and production — your innovation partner at every stage.

Why Our Capabilities Stand Out

More Than Machines — It’s How We Apply Them

What makes Poliform’s capabilities different isn’t just the equipment – it’s the thinking behind every process and the discipline in how we deliver.

Modern Machinery

Servo-driven injection molding systems designed for precision, energy efficiency, and high throughput.

Scalable Production

Whether it’s 500 parts or 50,000 – our setup adapts to your volume needs without compromising consistency.

Technical Rigor

Precision-focused approach across mold design, part validation, and quality control.

Advanced Tools & Systems

Use of servo-driven machines and smart inventory management to optimize performance and minimize waste.

Frequently Asked Questions

Have Questions About Capabilities? We’ve Got You Covered.

1. What materials can you work with?

We work with a wide range of engineering-grade and commodity plastics, based on part function, durability, and compliance needs.

2. What is your daily production capacity?

Our setup can produce thousands of components per day, depending on part size and complexity — including 1000 pcs/day at 5g scale.

3. Can you support low-volume or prototype runs?

Yes. We offer flexible batch sizes and support early-stage prototyping as part of our new product development service.

3. Do you provide finishing and post-molding operations?

Absolutely. We offer assembly, trimming, and surface finishing to deliver ready-to-use components.

3. How long does it take to develop a new mold?

Timelines vary by complexity, but most molds are designed, developed, and trialed within 3–5 weeks.